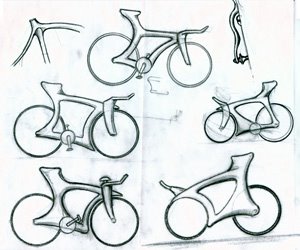

It has been a while since I have posted any sketches, so here are a few rough ones. These are quick little pursuit bike forms that I sketched last night while I was watching the Olympics on TV. I probably would have scrapped this page, but I kind of like the shape of the frame in the lower right-hand corner (yeah, I know the bike is missing a few vital parts, but hey, it’s just a thumbnail sketch). So what do these bikes have in common? They all have seats integrated into the frame. That idea is nothing new. I’ve seen it before on some of the one-off track frames of the 90’s. For most bikes the idea is totally impractical, but for high end track racing bikes and time trial machines, why not? The answer, of course, is that our good friends at the UCI don’t like these types of designs. Still, for the purpose of this post let’s just forget, for a few minutes at least, that they exist.

It has been a while since I have posted any sketches, so here are a few rough ones. These are quick little pursuit bike forms that I sketched last night while I was watching the Olympics on TV. I probably would have scrapped this page, but I kind of like the shape of the frame in the lower right-hand corner (yeah, I know the bike is missing a few vital parts, but hey, it’s just a thumbnail sketch). So what do these bikes have in common? They all have seats integrated into the frame. That idea is nothing new. I’ve seen it before on some of the one-off track frames of the 90’s. For most bikes the idea is totally impractical, but for high end track racing bikes and time trial machines, why not? The answer, of course, is that our good friends at the UCI don’t like these types of designs. Still, for the purpose of this post let’s just forget, for a few minutes at least, that they exist.

Even though most are now made with traditional diamond style frames, custom carbon fiber bikes are more prevalent than ever before. Several companies, Calfee for example, can provide a true custom machine to any customer who wants the qualities of carbon fiber in a bike with non-stock geometry. But why stop at the frame if you are going to go custom? If I ever get around to making a homemade carbon bike for myself, you can bet it will have an integrated seatpost and maybe even an integrated saddle. That’s a fine idea for a home built bike, but for the idea to be practical in production, even custom production, a true monocoque (single shell) design might not be the answer. Maybe the seat column/seat part could come be molded separately and then trimmed to sleeve onto a few standard frame sizes. These parts would then be epoxy bonded together just like the individual parts of a carbon tube set. The end result would be a seamless look that would not require separate tooling for every individual frame. I like the idea, but there are certainly a few problems to work out. With a design like this, it would be prudent to know exactly what seat height you want before commissioning your new frame. Even though I know my seat height to the millimeter, a bit of adjustment in height would probably be required for differences in crank arm length, pedal height, etc. An inset seat recessed into a carbon shell could allow for those necessary couple centimeters of adjustment. Some of you can probably point out several other challenges that would need to be overcome to make a frame design like this work. Yes, the idea is impractical and the UCI (back to them again) wouldn’t allow anyone to race a bike like this. Still, think of the advantages: improved aerodynamics, lighter weight, and a cool, unified look. Best of all, you would never have to worry about adjusting a seatpost again. That counts for something, right?

Leave a Reply