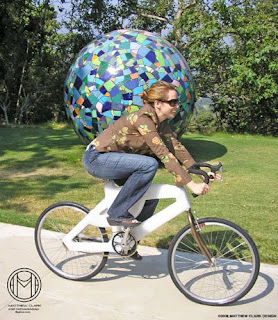

Matt Clark, an industrial designer in Rancho Palos Verdes, CA, sent me these pictures of a recycled plastic bike that he designed and built. You can see from the assembly picture that the frame has an internal triangulated rib structure, which gives it its rigidly. Before I heard from Matt, a reader named Adam emailed to tell me about the construction of the bike, which he saw in Burbank and was quite impressed with. “I even rode it and it works very well and isn’t even the slightest bit flimsy!!!! It was stunning” said Adam.

Matt Clark, an industrial designer in Rancho Palos Verdes, CA, sent me these pictures of a recycled plastic bike that he designed and built. You can see from the assembly picture that the frame has an internal triangulated rib structure, which gives it its rigidly. Before I heard from Matt, a reader named Adam emailed to tell me about the construction of the bike, which he saw in Burbank and was quite impressed with. “I even rode it and it works very well and isn’t even the slightest bit flimsy!!!! It was stunning” said Adam.

Instead of paraphrasing Matt to explain the concept, I’ll let him tell you about it in his own words:

The bicycle is aimed at improving and solving multiple issues involved in production. It is also designed to utilize automated processes and more cost efficient materials (plastics).

The bicycle is aimed at improving and solving multiple issues involved in production. It is also designed to utilize automated processes and more cost efficient materials (plastics).

The bicycle consists entirely of reinforced and unreinforced recyclable polypropylene. The patent-pending bicycle features a two component frame: the plastic INNERFRAME and the plastic outer structure, both dual components.Ideally, the material would be sourced from recycled plastic sources (IE: old bottles etc) to reduce environmental impact and costs.

The INNERFRAME, which gives the bicycle it’s rigidity, is most easily described as a spaceframe-like structure that features triangulation and molded “beams” to increase it’s strength. Additionally, this prototype, utilizes reinforced polypropylene for the inner chainstays. One main objective was to make the frame fully recyclable and it, absolutely, is.

The process would streamline bicycle production by providing pre-molded halves that could be either linear vibration or hot air welded together. All of the processes could be accomplished without the need to notch and individually weld each tube together and eliminates the heat treatments required for aluminum frames. This reduces the cost of production by reducing labor while simultaneously utilizing a more affordable material.

Interesting concept, so thanks to both Adam and Matt for letting me know about it. Another reader, Brian, just let me know that Bike Commuters has already posted about this design, so you can read more about it there. If any of you have questions or want more information about the design, you can contact Matt directly by email.

Interesting concept, so thanks to both Adam and Matt for letting me know about it. Another reader, Brian, just let me know that Bike Commuters has already posted about this design, so you can read more about it there. If any of you have questions or want more information about the design, you can contact Matt directly by email.

Update: It was pointed out to me that the title of this post is somewhat misleading because the prototype frame, which I called recycled, was actually made from virgin plastic. I said recycled in the title because the intent of Matt’s design concept is to produce the frame using recycled materials. Still, it would be more accurate to call this particular bike “recyclable” since the prototype was not made from recycled material. Sorry for any confusion.

Leave a Reply to Anonymous Cancel reply