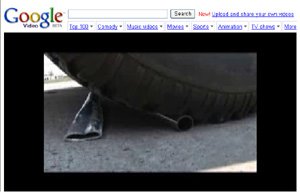

Anyone who is involved in the product development process is familiar with some form of destructive testing. Admit it, it is fun to push materials to their limit and watch them fail. This post is not really about a test per se, but more of a demonstration. Still, if you are interested in seeing a few bicycle tubes being crushed (and I know you are), check out this Google video from the folks at Litespeed. Brad, the company’s chief engineer, narrates the video as Scott drives a big crew cab pickup truck over a carbon tube, an aluminum tube, and finally a titanium tube. I won’t spoil the ending for you, but I am pretty sure you can guess which tube emerges intact. Stay tuned to the end. Brad seems to be pretty happy with the results as he laughs devilishly while the video closes.

Anyone who is involved in the product development process is familiar with some form of destructive testing. Admit it, it is fun to push materials to their limit and watch them fail. This post is not really about a test per se, but more of a demonstration. Still, if you are interested in seeing a few bicycle tubes being crushed (and I know you are), check out this Google video from the folks at Litespeed. Brad, the company’s chief engineer, narrates the video as Scott drives a big crew cab pickup truck over a carbon tube, an aluminum tube, and finally a titanium tube. I won’t spoil the ending for you, but I am pretty sure you can guess which tube emerges intact. Stay tuned to the end. Brad seems to be pretty happy with the results as he laughs devilishly while the video closes.

This demonstration does not, of course, simulate the stresses on a bike frame during normal use, but it does point to the toughness of titanium as a raw material. I enjoyed watching it and I did come away with a very valuable lesson; stay away from big F250 trucks while you are riding regardless of your frame material.

Leave a Reply